9. CORPORATE OFFICE & TRAINING CENTRE 2131 Airport Drive, Saskatoon, SK Canada S7L 7E1 Tel: 306.933.8585 U.S.A. Toll-Free: 1.866.663.8515 www.morris-industries.com Questions? email: info@morris-industries.com The policy of MORRIS INDUSTRIES LTD. is one of continuing improvement; therefore, the company reserves the right to change any specification without notice. PRINTED IN CANADA

1. morris-industries.com ENGINEERED BY AIR DRILL

4. Controlled Traffic Farming The Quantum has main frame tires on 9.8 ft (3m) centers, an important consideration for standardizing wheel-based soil compaction in controlled traffic fields. Plant more acres per day with the new 15 inch shank spacing and ShieldCore paired row opener A 70 ft Quantum with a 15 inch shank spacing and paired row opener working at 6 mph will plant the same number of acres as a 90 ft drill with a working speed of 4.5 mph.

2. Heavy Duty Hitch The pulling hitch has been completely redesigned on the Quantum. The new hitch uses 20% more steel and is connected to the frame with chrome pins that fit into hardened steel bushings. The low pull point design reduces draft load onto the front tires. A new greaseable articulating hitch clevis with excellent wear life is part of the new design. This hitch clevis is also used on the quad hitch at the back of the drill for attaching tow-behind carts. Frame Design The Quantum frame is 154% stronger than our previous drills. The 4x6 tubular steel frame features innovative joint welding made possible by Morris proprietary manufacturing technology. Frame sections are connected with 27% larger diameter chrome pins that slide into hardened steel bushings ensuring the Quantum is the strongest, most durable air drill we have ever made.

6. Rapid uniform crop emergence is the hallmark of well-designed seeding equipment - the first and most important step in maximizing yield potential. Poorly established fields never achieve their full yield potential. Consistent depth control, seed and fertilizer separation, and soil-seed contact are the dominant factors that influence rapid uniform crop emergence and minimize seed mortality. Trash Flow The trash flow characteristics of the Quantum have been adapted from the C2 Contour, the best trash flow design in the industry. The success of this design comes from maximizing the lowest catch point on the opener and reclining the opener shank 12 degrees. This design allows you to plant into taller stubble and create a more fluid flow of crop residue around the opener and shank. Eliminating bunching and piles of crop residue collecting on the shank of the opener is important during shallow seeding. These residue bunches interfere with the flow of soil around the opener and filling the furrow before packing resulting in uncovered seed and spotty germination.

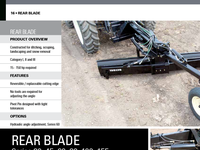

8. QUANTUM AIR DRILL Specifications and Options Base Size Models 40’ (12 m) 50’ (15 m) 60’ (18 m) 70’ (21 m) Weight (Includes Double Shoot Distribution) - 10” Spacing 25 cm Spacing 27,665 lb 12,549 kg 31,970 lb 14,501 kg 40,785 lb 18,500 kg 44,090 lb 19,999 kg - 12” Spacing 30 cm Spacing 26,085 lb 11,832 kg 30,030 lb 13,621 kg 38,335 lb 17,388 kg 41,210 lb 18,692 kg - 15” Spacing 38 cm Spacing 24,555 lb 11,138 kg 28,050 lb 12,723 kg 36,025 lb 16,341 kg 38,530 lb 17,477 kg Working Width - 10” (25 cm) - 12” (30 cm) - 15” (38 cm) 40’ (12 m) 50’ (15 m) 60’ (18 m) 70’ (21 m) Number of Shanks - 10” (25 cm) - 12” (30 cm) - 15” (38 cm) 48 40 32 60 50 40 72 60 48 84 70 56 Frame Width - Main - Wing Inner - Wing Outer 14.35’ (4.37m) 13.60’ (4.15m) N/A 14.35’ (4.37m) 13.60’ (4.15m) 5.03’ (1.53m) 14.35’ (4.37m) 13.65’ (4.16m) 10.15’ (3.09m) 14.35’ (4.37m) 15.65’ (4.77m) 13.16’ (4.01m) Transport Position - Width - Height - Length 17’ 10” (5.44m) 16’ 10” (5.13m) 33’ 10”(10.31m) 17’ 10” (5.44m) 16’ 10” (5.13m) 33’ 10”(10.31m) 17’ 10” (5.44m) 16’ 10” (5.13m) 33’ 10”(10.31m) 17’ 10” (5.44m) 19’ 1” (5.82m) 33’ 10”(10.31m) Tires - Main Frame Wheels (4) 600/50-22.5 (4) 600/50-22.5 (4) 600/50-22.5 (4) 600/50-22.5 - Wing Frame Front Castor Wheels Single Castor (2) 600/50-22.5 Single Castor (2) 600/50-22.5 Single Castor (4) 600/50-22.5 Single Castor (4) 600/50-22.5 - Wing Frame Rear Wheels (1 per wing) (2) 600/50-22.5 (1 per wing) (2) 600/50-22.5 (1 per wing) (4) 600/50-22.5 (1 per wing) (4) 600/50-22.5 Opener - Trip Out Force Maximum 800 lbs (363 kg) at 1200 psi (8274 kPa) - Packing Force 100 lbs to 230 lbs (45 kg - 104 kg) - Packer Wheel 4.50” x 16” Semi Pneumatic Otico tire 5.50” x 16” Semi Pneumatic Otico tire 5.50” x 16” Semi-Pneumatic 4.00” x 16” “V” Crown Opener to Ground Clearance 12” (30.5 cm) Frame to Ground Clearance 36” (91.4 cm) Frame Depth 84” (213.4 cm) center to center Rank to Rank Spacing 42” (106.7 cm) center to center Number of Ranks 3 Rows Shank to Shank Spacing 30” (75 cm) on 10” (25 cm) Spacing 36” (90 cm) on 12” (30 cm) Spacing 45” (114 cm) on 15” (38 cm) Spacing Weight Kit Optional Safety Lights Standard Hitch Clevis Standard - Category 4 Optional - Category 5 Safety Chain Standard Specifications are estimates and subject to change. Your Land Where innovation grows.

3. The reversible ‘anti-skew’ packer arm has a smooth design to eliminate catching of crop residue and is made from 2x3 inch structural tubing for outstanding durability. A unique zero lash castle joint is designed for consistent assembly and outstanding row to row depth precision. The compact linkage arms are made from 2x4 inch HSS tube and reduce stress on linkage pivots. The linkage pivots are all 1 inch chrome pins inside hardened plastic bushings that eliminate steel on steel wear. Precision Welding – Traps soil between surface beads, making soil wear on soil, not steel Optimized Weld Bead Size – Avoids excess soil build-up on opener while protecting all surfaces Increased Shank Tip Angle – For excellent ground penetration in wet soil conditions Increased Wear Life – New wear guard extends life to protect IP boots DURABLE, LONG-LASTING GROUND ENGAGING TOOLS Larger Protection Area 3x larger surface is protected compared to previous generation openers New Improved Row Unit Features The shank holder has been extended to improve trip action for faster release off rocks. Large Single Castor Tires The Quantum uses a 600/50-22.5 tire across the machine. This large single wheel castor improves the stability of the Quantum drill during operation in the field and during transport. The larger diameter tires and 19% increase in tire height smooths the passage of the machine through field ruts and washouts. Tires and hubs are fully interchangeable from wings to mainframe if rotation is desired to maximize tire life. Castor Specifications: • Main castors: 4.5 inch diameter castor with greaseable pivot bushing on a 15,000 lb hub • Wing castors: 3 inch diameter castor with greaseable pivot bushing on a 15,000 lb hub New Stainless-Steel Divider Heads Using stainless-steel increases the lifespan of the divider head. The new design is less prone to plugging due to the consistent smooth surface on the inside preventing build-up of fertilizer and seed dust. A larger head size with 28mm secondary hose openings is designed for passage of larger seeds. The quick coupler system makes it convenient for inspection. Durability

5. Broadest Range of Row Unit Spacing The Quantum has a wide range of row unit spacing options. The design of the frame adapts to imperial and metric spacing. Imperial: 10, 12 and 15 inch spacing all at the exact working width of the drill. Available in 40, 50, 60 and 70 ft Metric: 25 cm, 30 cm and 38 cm spacing on 12, 15, 18 and 21 m width drills Packer Wheel Options 5.50” x 16” Semi-Pneumatic 4.50” x 16” Semi-Pneumatic Otico tire 5.50” x 16” Semi-Pneumatic Otico tire 4.00” x 16” “V” Crown Active Opener Hydraulics The new Quantum uses an active hydraulic system to control opener pressure. It features a reducing system to minimize hydraulic flow requirements during operation. The new controller has several user-friendly options such as single touch opener lift and lower and adjustable opener pressure from the tractor. This new hydraulic system is compatible with the Topcon X35 control system which adds Autolift, a feature that automatically lifts and lowers openers at headlands and Autopack, a system that allows the user to change opener packing force on the X35 monitor. Increased Depth Range The Quantum opener cam is the same proven system utilized on the C2 Contour. The notched cam-and-pin system adjusts depth at 1/4 inch intervals. Rotate the cam by hand and insert the pin to lock in the desired seeding depth. The Quantum row unit features a depth shim system to allow for deeper seeding. There is a removable shim under the depth cam and removing the shim results in an increase in 1 inch seeding depth. Productivity Reduced Downtime for Your Convenience Industry Leading Flotation Float through wet spots with 15% more tire area on the ground. There is approximately 12lb drill weight/in 2 of tire foot print.

7. 2.125 " Seed Depth 4.00 " Fertilizer Depth 1 .00 " Seed Depth 1 .79 " Fertilizer Depth -0.875 " Fertilizer Depth -0.375 " Seed Depth 3.5 " Seed Depth 1 .00 " Seed Depth -1.50 " Seed Depth Elevation Change of 10" (254 mm) 1 .00 " Seed Depth 1 .75 " Fertilizer Depth (2 to 1 Ratio) (1 to 1 Ratio) 1 .00 " Seed Depth 1 .75 " Fertilizer Depth 1 .00 " Seed Depth 1 .75 " Fertilizer Depth Normal Drop of 5" Rise of 5" Normal Drop of 5" Rise of 5" Normal Drop of 5" Rise of 5" Competitor "A" Morris Competitor "B" Improved Seed Distribution Across the Machine There is a consistent amount of seed delivered to each drill section with Morris seeding systems. This is because the spiral fluted metering wheel on Morris air carts is specifically sized according to the rows the divider head feeds. The quantity of seed delivered to each divider head over time has had outstanding repeatability in our air system evaluations. After reaching the head, a random split occurs at the head and this determines how much seed is delivered to each opener. 5 cm (2”) seed fe r tiliz er 2 cm (3/4”) The side band double-shoot opener first places a distinct seed row 2 inch (5 cm) to the side of the knife followed by a fertilizer band which is placed directly behind the knife and 3/4 inch (2 cm) below the seedbed. This patented design results in outstanding fertilizer - seed separation and improved seed bed consistency by minimizing soil fracturing. 1.25 cm (1/2”) seed fertilizer The narrow knife single-shoot opener is a single-shoot opener that places a narrow 1/2 inch (1.25 cm) ribbon of seed in each seed row. This opener cuts a smooth narrow channel for seed to be placed, and has the lowest soil disturbance of the openers available. This opener has proven to be a popular choice with growers with sticky, high clay content soils. 7.6 cm (approx. 3” ) seed fertilizer The spread tip single-shoot opener places a 3 inch (7.6 cm) wide ribbon of seed in each seed row. This opener cuts a smooth level seedbed resulting in very consistent seed placement and has been designed to minimize soil disturbance. The spread tip opener, with its high seed bed utilization is an excellent choice for farmers who apply low to moderate fertilizer rates with the seed. Agronomic Performance Depth Control The Quantum row unit utilizes parallel linkage with a 1:1 opener to packer ratio. Morris was the first company to introduce a parallel link independent hoe opener with a 1:1 opener to packer movement. This superior design results in the most precise depth control and ground following among independent hoe opener drills. How It Works The working depth that the opener moves through the soil is regulated by the packer tire. The parallel linkage feature ensures that the depth control and the seed opener angle of entry into the soil is exact over a range of travel of 16 inch. The practical significance of this during field operation is the opener will not carve deeper when travelling over the crowns of hills and is much less prone to losing seed placement when running through shallow depressions like water runs. Outstanding Product Separation Morris has measured the impact of fertilizer rates on crop establishment across a wide variety of soils and climatic conditions, in field scale strip trials and replicated small plot research, over the past ten years. We have come away from this experience with confidence that our double-shoot openers consistently maintain a high degree fertilizer and seed separation, and this results in our openers being relatively insensitive to fertilizer rates. The patented paired row double-shoot opener places two distinct rows of seeds 4 inch (10 cm) apart with fertilizer placed centrally and 3/4 inch (2 cm) below the seed rows. The 12 inch (30 cm) shank spacing, paired row opener combination provides an 8 inch (20 cm) seed row spacing. Narrow row spacing closes the crop canopy more rapidly setting the stage for improved sunlight capture, water use efficiency and crop competition. Angled carbide faces on the opener minimizes soil fracturing for excellent seed bed consistency and outstanding seed to fertilizer separation. Available only on 12 inch spacing. 4” (10 cm ) 3/4” (2 cm) seed seed fertilize r 8” (20 cm) 4” (10 cm) seed seed fertilize r