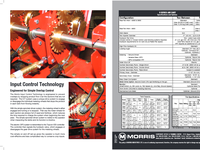

2. N41575 Can be used on all spacings offered and can be used for seeding or band - ing. Provides approximately 7.6 cm (3”) to 10.2 cm (4”) seed spread directly behind the shank. Features an upper steel tube for better durability. N20886 - 22.8 cm (9”) spacing N20885 - 30.5 cm (12”) spacing Cast boot adaptable to 22.8 cm (9”) or 30.5 cm (12”) spacing simply by exchang - ing a splitter that mounts behind the boot. General broadcast pattern. Seed spread is approximately 10.2 cm to 12.7 cm (4-5”). N10988 For 30.5 cm (12”) spacing but can be used on 22.8 cm (9”) and 25.4 cm (10”) spac - ing if 30.5 cm (12”) sweeps are installed. The seed is placed in a broadcast pattern with little row definition for excellent swath support. Seed spread is approximately 10.2 cm to 12.7 cm (4-5”). N22816 Can be used on all spacings offered and can be used for seeding or band - ing. Provides approximately 11.4 cm (4 1/2”) seed spread directly behind the shank. N10572 Seeding/banding boot can be used on all spacings offered. Excellent for band - ing fertilizer as the spread is very small approximately 5 cm (2”) to 7.6 cm (3”), reducing nitrogen losses. Paired Row S25962 “C” Shank Paired Row Dual Shoot Opener fits shanks with a 4.4 cm (1 3/4”) or 5.7 cm (2 1/4”) hole spacing. Replaceable chrome tip, with an optional carbide point is adjustable for wear and fertilizer placement. The fertilizer depth is adjustable to 2, 3.8, or 5.7 cm (3/4”, 1 1/2”, 2 1/4”) below the seed rows ensuring separation. Seed is placed in two rows 7.6 cm (3”) apart. Seed spread is approximately 2.5 cm (1”). Use in all soil conditions and with 8.9 cm (3 1/2”) mounted packer wheels. Dual Purpose Concept 2000 Seeding & Tillage System Flexibility and contourability is a trademark of Morris’ floating frame design featuring independent wing sections. Floating frame sections, with a tricycle suspension and patented frame coupling assures flexibility while easing the stress on the frame member joints. This allows the frames to adjust to and follow the contours of the land. (Because of the unique floating frame design Morris does not recommend the use of mechanical end markers). The tricycle suspension is created through three support points on each frame. A dual castor centered between the walking beam axles give the tricycle suspension for the mainframe. Similarly, the centered gauge wheel, walking beam axle and ball joint pivots maintain the three point support on the wing frames. Independent hitch trusses are used to pull the frames. Stress induced by the trips is evenly distributed across the hitching, greatly extending the service life of the machine. The Concept 2000 dual purpose system proves invaluable to farming operations worldwide. Whether you require a heavy duty chisel plow to till soil, cut through residue, and leave an exceptional field finish or the accuracy of a precision air seeding system, the Concept 2000 offers the best of both worlds. Precision seeding system doubles as heavy duty chisel plow The Concept has one of the shortest contour lengths in the industry - only 2.4 m (96”) and a true floating hitch to maintain consistent seeding or tilling depth over sharp knolls, hills and draws. The walking beam axles, placed near the rear of the frame, add another advantage. Even in the most challenging conditions, the machine follows the terrain maintaining uniform depth across the entire machine. Optional mud scrapers are available for the inner tires to aid in wetter conditions. Universal Ball Joint The unique tripping characteristic reduces stress on the trip components and frame mem - bers. Carbide Point Option The Carbide Point is designed to enhance the Morris Gumbo Boot Kits (S25962). The Carbide Point’s durability will increase the number of acres between point replacement, result - ing in less down time and increased productivity during the critical seeding season. Less wear also ensures consistency of depth control. Anhydrous Option The application of anhydrous or liquid fertilizer is available with Morris double shoot openers. On conventional “C” shank openers the 1.27 cm (1/2”) poly tube inserts down the standard fertilizer tube providing a positive seal. Safe levels of actual nitrogen will vary with soil conditions at the time of application. Consult your local agronomist for recommended levels in your area. Note: For optimum placement and minimum soil disturbance, seeding speed should not exceed 5 m.p.h. Soil moisture levels and soil types may affect opener operation. The Concept 2000 features three trip assembly options - the 755LH 340 kg (750 lb) trip, 250 kg (550 lb) and the 186 kg (400 lb) trip. All Morris trips accept a variety of Morris seed and fertilizer boots, as well as other standard sweeps and spikes. The 755LH trip combines the best features of spring cushion and over center trip assemblies. The trip is maintenance-free, requiring no greasing. The shank is held rigid in its home position. Rotational movement of the pivot points is limited, resulting in minimal wear on the bushings. A 30.5 cm (12”) sweep to ground clearance in transport makes it easier to travel over high crowned roads. This clearance also provides access when changing openers. Weight is transferred to the front of the machine in transport position. This provides greater stability, even with the mounted packer or harrow option. Single point safety latch. The Concept 2000 keeps you at work in the most demanding trash conditions. The four row Z trip pattern allows trash to flow freely through the machine. To improve trash clearance capabilities, the spacing between ranks increases from 68.6 cm (27”) between the first and second rows to 78.7 cm (31”) between the second and third, and to 101.6 cm (40”) between the third and fourth. In combination with the short contour length of the machine and the extra high ground clearance provided by the trip assembly, the increase in distance between ranks from front to back provides superior performance in heavy trash conditions. A standard feature of the Concept 2000 is the hydraulic and mechanical depth control system for seeding and tillage operations. This feature makes it easy to set machine depth with a convenient single point adjustment. The Hydraulic depth stop valves ensure consistent working depth by isolating the implement’s hydraulics from the tractor in tillage opera - tions. It is recommended that the mechanical depth stops are used when seeding. The Concept 2000’s parallel lift depth control system keeps the machine level from front to back, providing superior contouring for consistent seed depth. The system provides excellent ground transport. A unique lifting linkage raises the front tire on the wing walk - ing axles when turning on headlands. Lifting linkage prevents gouging and ridging for a smoother field finish. Floating frame design features independent wing sections. Universal Arm with quick detach pin for changing packers and harrows. A mounted harrow option pro - vides extra soil levelling for a smoother field finish. A Mounted packer option for on-row packing ensures excellent seed to soil contact. The new Morris 250 kg (550 lb) trip features a 2.54 cm (1”) shank for extra durability. Higher durability – recoil is much softer with the hydraulic trip. Hydraulic pressure control – to clear obstacles in the field, the farmer can operate the tractor remote to decrease the system pressure, and then increase the pressure back to the pre-set operating pressure once the obstacles have been cleared. A ball valve can be used to isolate the accumulator circuit once the pressure has been set. In this configuration trip out force remains set at one point, and can not be changed from the tractor. Hydraulic tyne option – Trip out pressure can be increased or decreased on the go. Adjustable trip out force – during hard pulling, trip out can be set higher to avoid unnecessary tripping. In rocky or obstacle laden fields, trip out force can be reduced in order to clear large solid obstacles. The new Hydraulic tyne can be locked up for both storage & and spacing. For example, lock out every second tyne for summer cropping prac - tices (allows farmers with 38 cm (15”) spacing to summer crop on 76 cm (30”) spacing).

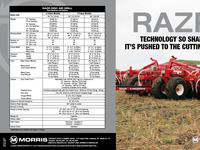

1. Concept 2000 Air Seeding & Tillage System e s a B l e d o M d ' t x E l e d o M h t d i W g n i k r o W r e b m u N s k n a h S f o t r o p s n a r T t h g i e W p i r T H L 5 5 7 h t i w h t d i Wt h g i e H " 2 1" 0 1" 9" 2 1" 0 1" 9" 2 1" 0 1" 9" 2 1" 0 1" 9 m c 5 . 0 3m c 4 . 5 2m c 9 . 2 2m c 5 . 0 3m c 4 . 5 2m c 9 . 2 2m c 5 . 0 3m c 4 . 5 2m c 9 . 2 2m c 5 . 0 3m c 4 . 5 2m c 9 . 2 2 : n o i t c e S 3 t r o p s n a r T r a l u g e R ' 3 2 ' 3 2 ' 4 2 ' 5 . 3 2 3 29 21 3 " 7 ' 7 1' 1 1" 7 ' 1 1" 1 ' 1 1 b l 5 7 5 , 1 1b l 5 6 6 , 2 1b l 5 0 3 , 2 1 m 7 m 1 0 . 7 m 1 3 . 7 m 6 1 . 7 m 6 3 . 5 m 5 3 . 3 m 3 5 . 3 m 8 3 . 3 g k 1 6 2 , 5 g k 7 5 7 , 5 g k 3 9 5 , 5 ' 5 2 ' 5 2 ' 6 2 ' 5 2 5 21 33 3 " 7 ' 7 1' 2 1" 5 ' 2 1" 0 1 ' 1 1 b l 5 4 0 , 2 1b l 0 9 1 , 3 1b l 5 7 7 , 2 1 m 2 6 . 7 m 2 6 . 7 m 2 9 . 7 m 2 6 . 7 m 6 3 . 5 m 6 6 . 3 m 8 7 . 3 m 1 6 . 3 g k 5 7 4 , 5 g k 5 9 9 , 5 g k 7 0 8 , 5 ' 9 2 ' 9 2 ' 1 3 ' 5 . 9 2 9 27 39 3 " 6 ' 7 1' 4 1" 8 ' 4 1' 4 1 b l 0 8 1 , 3 1b l 5 4 9 , 3 1b l 0 1 1 , 4 1 m 8 . 8 m 4 8 . 8 m 5 4 . 9 m 9 9 . 8 m 3 3 . 5 m 7 2 . 4 m 7 4 . 4 m 7 2 . 4 g k 1 9 9 , 5 g k 9 3 3 , 6 g k 4 1 4 , 6 ' 1 3 ' 1 3 ' 5 . 2 3 ' 1 3 1 39 31 4 " 6 ' 7 1" 0 1 ' 4 1" 6 ' 5 1" 0 1 ' 4 1 b l 0 5 6 , 3 1b l 0 7 4 , 4 1b l 0 8 5 , 4 1 m 5 4 . 9 m 5 4 . 9 m 1 9 . 9 m 5 4 . 9 m 3 3 . 5 m 2 5 . 4 m 2 7 . 4 m 2 5 . 4 g k 5 0 2 , 6 g k 7 7 5 , 6 g k 7 2 6 , 6 ' 3 3 ' 3 3 ' 4 3 ' 5 . 2 3 3 31 43 4 " 6 ' 7 1" 0 1 ' 5 1" 4 ' 6 1" 7 ' 5 1 b l 0 3 2 , 4 1b l 5 9 0 , 5 1b l 5 5 1 , 5 1 m 6 0 . 0 1 m 6 0 . 0 1 m 6 3 . 0 1 m 1 9 . 9 m 3 3 . 5 m 3 8 . 4 m 8 9 . 4 m 5 7 . 4 g k 8 6 4 , 6 g k 1 6 8 , 6 g k 9 8 8 , 6 : n o i t c e S 3 t r o p s n a r T e d i W ' 2 3 ' 2 3 ' 4 3 ' 5 . 2 3 2 31 43 4 " 6 ' 0 2' 4 1" 8 ' 4 1' 4 1 b l 0 6 0 , 4 1b l 0 1 9 , 4 1b l 0 3 0 , 5 1 m 5 7 . 9 m 5 7 . 9 m 6 3 . 0 1 m 1 9 . 9 m 5 2 . 6 m 7 2 . 4 m 7 4 . 4 m 7 2 . 4 g k 1 9 3 , 6 g k 7 7 7 , 6 g k 2 3 8 , 6 ' 4 3 ' 4 3 ' 6 3 ' 4 3 4 33 45 4 " 6 ' 0 2" 0 1 ' 4 1" 6 ' 5 1" 0 1 ' 4 1 b l 0 3 5 , 4 1b l 5 3 4 , 5 1b l 0 0 5 , 5 1 m 6 3 . 0 1 m 6 3 . 0 1 m 7 9 . 0 1 m 6 3 . 0 1 m 5 2 . 6 m 2 5 . 4 m 2 7 . 4 m 2 5 . 4 g k 5 0 6 , 6 g k 6 1 0 , 7 g k 5 4 0 , 7 ' 6 3 ' 6 3 ' 5 . 7 3 ' 5 . 5 3 6 35 47 4 " 6 ' 0 2" 0 1 ' 5 1" 4 ' 6 1" 7 ' 5 1 b l 0 1 1 , 5 1b l 0 6 0 , 6 1b l 5 7 0 , 6 1 m 7 9 . 0 1 m 7 9 . 0 1 m 3 4 . 1 1 m 2 8 . 0 1 m 5 2 . 6 m 3 8 . 4 m 8 9 . 4 m 5 7 . 4 g k 8 6 8 , 6 g k 0 0 3 , 7 g k 7 0 3 , 7 ' 8 3 ' 8 3 ' 1 4 ' 5 . 8 3 8 39 41 5 " 2 ' 0 2' 7 1" 1 ' 8 1' 7 1 b l 0 9 1 , 5 1b l 5 8 1 , 6 1b l 5 3 3 , 6 1 m 8 5 . 1 1 m 8 5 . 1 1 m 0 5 . 2 1 m 3 7 . 1 1 m 5 1 . 6 m 8 1 . 5 m 1 5 . 5 m 8 1 . 5 g k 5 0 9 , 6 g k 7 5 3 , 7 g k 5 2 4 , 7 ' 0 4 ' 0 4 ' 5 . 2 4 ' 0 4 0 41 53 5 " 2 ' 0 2" 8 ' 7 1" 1 1 ' 8 1" 8 ' 7 1 b l 0 6 6 , 5 1b l 0 1 7 , 6 1b l 5 0 8 , 6 1 m 9 1 . 2 1 m 9 1 . 2 1 m 5 9 . 2 1 m 9 1 . 2 1 m 5 1 . 6 m 8 3 . 5 m 7 7 . 5 m 8 3 . 5 g k 8 1 1 , 7 g k 5 9 5 , 7 g k 9 3 6 , 7 ' 2 4 ' 2 4 ' 4 4 ' 5 . 1 4 2 43 55 5 " 2 ' 0 2" 8 ' 8 1" 9 ' 9 1" 5 ' 8 1 b l 0 4 2 , 6 1b l 5 3 3 , 7 1b l 0 8 3 , 7 1 m 0 8 . 2 1 m 0 8 . 2 1 m 1 4 . 3 1 m 5 6 . 2 1 m 5 1 . 6 m 9 6 . 5 m 2 0 . 6 m 1 6 . 5 g k 2 8 3 , 7 g k 0 8 8 , 7 g k 0 0 9 , 7 n o i t c e S 5 0 5 ' 0 5 ' 4 5 ' 5 . 0 5 0 55 67 6 " 3 ' 3 2" 8 ' 8 1" 5 ' 9 1" 5 ' 8 1 b l 5 5 8 , 2 2b l 5 8 3 , 4 2b l 5 3 4 , 4 2 m 4 2 . 5 1 m 4 2 . 5 1 m 6 4 . 6 1 m 9 3 . 5 1 m 9 0 . 7 m 9 6 . 5 m 2 9 . 5 m 1 6 . 5 g k 9 8 3 , 0 1 g k 4 8 0 , 1 1 g k 7 0 1 , 1 1 2 5 ' 2 5 ' 6 5 ' 2 5 2 57 69 6 " 3 ' 3 2" 8 ' 8 1" 5 ' 9 1" 5 ' 8 1 b l 5 2 3 , 3 2b l 0 1 9 , 4 2b l 5 0 9 , 4 2 m 5 8 . 5 1 m 5 8 . 5 1 m 7 0 . 7 1 m 5 8 . 5 1 m 9 0 . 7 m 9 6 . 5 m 2 9 . 5 m 1 6 . 5 g k 2 0 6 , 0 1 g k 3 2 3 , 1 1 g k 0 2 3 , 1 1 6 5 ' 6 5 ' 1 6 ' 5 . 6 5 6 53 75 7 " 3 ' 4 2" 8 ' 8 1" 5 ' 9 1" 5 ' 8 1 b l 5 2 4 , 3 2b l 0 8 1 , 5 2b l 0 5 1 , 5 2 m 7 0 . 7 1 m 7 0 . 7 1 m 9 5 . 8 1 m 2 2 . 7 1 m 9 3 . 7 m 9 6 . 5 m 2 9 . 5 m 1 6 . 5 g k 8 4 6 , 0 1 g k 5 4 4 , 1 1 g k 2 3 4 , 1 1 8 5 ' 8 5 5 . 2 6 ' 8 5 8 55 77 7 " 3 ' 4 2" 8 ' 8 1" 5 ' 9 1" 5 ' 8 1 b l 5 9 8 , 3 2b l 5 0 7 , 5 2b l 0 2 6 , 5 2 m 8 6 . 7 1 m 8 6 . 7 1 m 5 0 . 9 1 m 8 6 . 7 1 m 9 3 . 7 m 9 6 . 5 m 2 9 . 5 m 1 6 . 5 g k 1 6 8 , 0 1 g k 4 8 6 , 1 1 g k 5 4 6 , 1 1 0 6 ' 0 6 ' 4 6 ' 5 . 9 5 0 67 79 7 " 3 ' 4 2" 8 ' 8 1" 5 ' 9 1" 5 ' 8 1 b l 5 7 4 , 4 2b l 0 3 3 , 6 2b l 5 9 1 , 6 2 m 9 2 . 8 1 m 9 2 . 8 1 m 1 5 . 9 1 m 4 1 . 8 1 m 9 3 . 7 m 9 6 . 5 m 2 9 . 5 m 1 6 . 5 g k 5 2 1 , 1 1 g k 8 6 9 , 1 1 g k 7 0 9 , 1 1 S N O I T A R U G I F N O C E M A R F e s a B l e d o M d ' t x E l e d o M e m a r F n i as Mg n i W r e n ns Ig n i W r e t us On o i s n e t x Es e r i T ' 2 1 m 6 6 . 3 ' 5 1 m 7 5 . 4 ' 6 m 3 8 . 1 ' 9 m 4 7 . 2 ' 2 1 m 6 6 . 3 ' 6 m 3 8 . 1 ' 9 m 4 7 . 2 2 k n a h S 4 k n a h S e e S w o l e B 3 2 m 7 I 5 2 m 2 6 . 7 I 9 2 m 8 . 8 I I 1 3 m 5 4 . 9 I I 3 3 m 6 0 . 0 1 I I 2 3 m 5 7 . 9 I I 4 3 m 6 3 . 0 1 I I 6 3 m 7 9 . 0 1 I I 8 3 m 8 5 . 1 1 I I 0 4 m 9 1 . 2 1 I I 2 4 m 0 8 . 2 1 I I 0 5 m 4 2 . 5 1 I I I 2 5 m 5 8 . 5 1 I I I 6 5 m 7 0 . 7 1 I I I 8 5 m 8 6 . 7 1 I I I 0 6 m 9 2 . 8 1 I I I p i r T m s i n a h c e M 0 0 4 n o i h s u C g n i r p S . s l o o t e g a l l i t e e r g e D 7 4 s t i f s e r t n e C ) m c 4 . 4 ( " 4 / 3 - 1 h t i w k n a h S ) m c 1 . 5 ( " 2 x ) m c 4 5 . 2 ( " 1 . ) g k 0 8 1 ( b l 0 0 4 e c r o F p i r T . e c n a r a e l C e m a r F o t p e e w S ) m c 6 . 8 6 ( " 7 2 . g n i c a p s ) m c 4 . 5 2 ( " 0 1 d n a ) m c 9 . 2 2 ( " 9 n o e l b a l i a v A 0 5 5 n o i h s u C g n i r p S . s l o o t e g a l l i t e e r g e D 7 4 s t i f s e r t n e C ) m c 4 . 4 ( " 4 / 3 - 1 h t i w k n a h S ) m c 1 . 5 ( " 2 x ) m c 4 5 . 2 ( " 1 . ) g k 8 4 2 ( b l 0 5 5 e c r o F p i r T . e c n a r a e l C e m a r F o t p e e w S ) m c 6 . 8 6 ( " 7 2 . g n i c a p s ) m c 5 . 0 3 ( " 2 1 d n a ) m c 4 . 5 2 ( " 0 1 , ) m c 9 . 2 2 ( " 9 n o e l b a l i a v A H L 5 5 7 p i r T c i t a m o t u A k n a h S ) m c 1 . 5 ( " 2 x ) m c 8 1 . 3 ( " 4 / 1 - 1 . s l o o t e g a l l i t e e r g e D 0 5 s t i f s e r t n e C ) m c 2 7 . 5 ( " 4 / 1 - 2 h t i w . ) g k 0 4 3 ( b l 0 5 7 e c r o F p i r T . e c n a r a e l C e m a r F o t p e e w s ) m c 2 . 6 7 ( " 0 3 . g n i c a p s ) m c 5 . 0 3 ( " 2 1 d n a ) m c 4 . 5 2 ( " 0 1 , ) m c 9 . 2 2 ( " 9 n o e l b a l i a v A p i r T c i l u a r d y H k n a h S ) m c 1 . 5 ( " 2 x ) m c 8 1 . 3 ( " 4 / 1 - 1 . s l o o t e g a l l i t e e r g e D 0 5 s t i f s e r t n e C ) m c 2 7 . 5 ( " 4 / 1 - 2 h t i w . e c n a r a e l C e m a r F o t p e e w s ) m c 2 . 6 7 ( " 0 3 . ) g k 8 1 3 - g k 8 6 ( s b l 0 0 7 - 0 5 1 e l b a t s u j d a e c r o F p i r T . g n i c a p s ) m c 5 . 0 3 ( " 2 1 d n a ) m c 4 . 5 2 ( " 0 1 , ) m c 9 . 2 2 ( " 9 n o e l b a l i a v A h t g n e L l l a r e v s O l e d o M l l a n o ) m 3 9 . 7 ( ' 6 2 h t p e D e m a rs Fl e d o M l l a n o ) m 9 5 . 2 ( " 2 0 1 s w o s R l e d o M l l a n o s w o R 4 d r a d n a t S , s t h g i L y t e f a n S i a h C y t e f a S s n o i t p O s w o r r a H d e t n u o M d n a , s r e k c a P d e t n u o M , s r e p a r c S d u M L A N O I T P O - S N O I T A R U G I F N O C E R I T I - e r i T e m a r F n i a D M e g n a R d a o L I F 5 1 x L 5 . 9 ) 4 ( e m a r F g n iD We g n a R d a o L I F 5 1 x L 5 . 9 ) e m a r f r e p 2 ( l e e h W e g u a G n i a D Me g n a R d a o L I F 5 1 x L 5 . 9 ) 2 ( l e e h W e g u a G g n iD We g n a R d a o L I F 5 1 x L 5 . 9 ) e m a r f r e p 1 ( I I - e r i T e m a r F n i aD Me g n a R d a o L I F 5 1 x L 1 1 ) 4 ( e m a r F g n iD We g n a R d a o L I F 5 1 x L 5 . 9 ) e m a r f r e p 2 ( l e e h W e g u a G n i aD Me g n a R d a o L I F 5 1 x L 1 1 ) 2 ( l e e h W e g u a G g n iD We g n a R d a o L I F 5 1 x L 1 1 ) e m a r f r e p 1 ( I I I - e r i T e m a r F n i aF Me g n a R d a o L I F 5 1 x L 1 1 ) 4 ( e m a r F g n iD We g n a R d a o L I F 5 1 x L 5 . 9 ) e m a r f r e p 2 ( l e e h W e g u a G n i aF M e g n a R d a o L I F 5 1 x L 1 1 ) 2 ( l e e h W e g u a G g n iD We g n a R d a o L I F 5 1 x L 1 1 ) e m a r f r e p 1 ( The walk-through tank design creates a firm standing platform with fill lids at waist level. More capacity, user friendly features, precise metering and proven distribution - whether you are changing product or setting rates, the clean basic design and operation of the EIGHT Series XL Air Cart lets you simply and easily get on with the task at hand. As your cropping practices change, the EIGHT Series XL adapts right along with you. Stackable collectors allow quick and easy change over from single to double shoot. Simply slide a rod to divert product from one air stream into another. Spiral fluted metering wheels gently roll product into the air stream, accurately metering fine to coarse seed and fertilizer. Patented flat fan divider heads maintain the smooth horizontal flow of product as it leaves the primary runs to divide into the secondary runs. The abrupt directional change common to vertical divider heads is eliminated. Outlets on the Flat Fan Divider are matched with metering wheel width for superior overall metering accuracy. All models are equipped with a 25.4 cm (10”) auger for a fast fill. Tank sizes: 6,550 L (180 bu) to 10,910 L (300 bu). Tow between & tow behind configurations. Loading auger: 17.8 cm (7”) on 7180 models 20.3 cm (8”) on 7240 & 7300 models. 7000 Air Carts feature walk through tank design. Very accurate seed & fertilizer calibration. Single, double shoot capability. High efficiency fan. 7000 Series air carts - field proven, easy to use The high efficiency air system design and 13” diameter fan provide a low horsepower draw from the tractor hydraulics. The Posi-Drive Transmission uses a positive lock on all drive sprockets to deliver smooth and reliable metering. The positive ground drive from the Air Cart wheel ensures precise product rates at all times. EIGHT Series XL complete with liquid tank option. Spiral fluted metering wheels move the prod - uct smoothly into the air stream. 2-3 Meter Controlled Traffic Air Carts EIGHT Series XL precision air carts - more capacity, more features Tank sizes: 8,730 L (240 bu.) to 15,239 L (630 bu.) Tow between & tow behind configurations Overall width: 3.78 m Overall height: 4.6 m 8630 EIGHT Series XL with quad steer. PRINTED IN CANADA 1010.500 CORPORATE OFFICE & TRAINING CENTRE - 2131 Airport Drive, Saskatoon, SK Canada S7L 7E1 Telephone: 306.933.8585 Fax: 306.933.8626 www.morris-industries.com Questions? email: info@morris-industries.com The policy of MORRIS INDUSTRIES LTD. is one of continuing improvement; therefore, the company reserves the right to change specifications without notice. Morris Concept 2000 Specifications and Options