2. Achieving the perfect balance of reliability and precision, the new 9-Series Air Cart comes with a list of next generation innovations. Advancements include Input Control Technology, new tank configurations, a left-side auger for easier access, a redesigned stairway and the Topcon X30 console. Redesigned tank and stairway The new tank shape on the 9-Series is designed to increase filling efficiencies and operator safety. The new stairway and walkway improve access to the tank lids. Ascending or descending the stairway is similar to how stairs are used at home. Handrails around the walkway platform and down the stairway provide excellent protection for a more secure and safe work area. Easier access The auger and conveyor is now on the left side of the air cart for easier access when filling. A new 6-function wireless remote is included with the hydraulic assist to reduce operator fatigue from handling loose wires. The provided lanyard for the remote will allow the operator to safely use two hands when necessary. New transmission covers have been added for added operator safety on all carts. Quick detach straps are provided on the Standard Drive to allow easy access to the Quick Change sprockets. New walkway and tank lid design The new walkway is positioned to allow the operator more room to work and avoid dust when filling the tanks. The improved lid design incorporates a gas cylinder to assist the operator when opening and closing the tanks. The handle is also repositioned so the operator does not need to stand above the lids to open them. The lids can then rotate to sit along the tank panel and reduce clutter on the walkway. Access to stairway from auger side The stairway has been relocated to the rear of the air-cart and can be accessed from the auger side. It also utilizes a retractable section to provide low step height when in use and then slide up and lock out of the way for improved ground clearance. The sliding section has two larger gas cylinders that help lift and hold the stairs until locked in position. A spring-loaded pin has been added to reduce latch time. More efficient meter-bodies The Meter-bodies have been updated to include single person operation of the inspection and calibration access doors. The operator can quickly inspect the seed-plate that is each meter-body. The changed calibration doors will also speed up calibration time because the operator does not have to pick up parts from the ground. The meter-body for the 9800 air cart has been widened to accommodate up to 10 metering wheels. This will allow the operator to utilize larger seeding units. Tanks easier to fill Filling of the tanks has been made easier by designing the tank lids to be closer together than before. With the optional hydraulic assist the operator can now use the wireless controller to adjust the positioning of the spout on the auger/conveyor without having to move the hopper from the unloading area or coming down from on top of the air-cart. More efficient disconnecting The distribution hose has been updated to include Quick couplers where the drill and air-cart connect to make disconnecting more efficient. High-efficient fan An industrial piston-type hydraulic motor powers the 17” diameter forward curved fan and large hydraulic lines decrease flow restriction for less heat build up under higher fan speeds. A dual fan option is available for large width seeding tools. Precision Metering The time-proven spiral fluted metering wheel is the center of the metering system. The spiral flute provides a continuous flow of product into the air stream. All-in-one seed plates save time, one quick change lets you accurately meter fine, medium or coarse products. Smooth horizontal flow of product The patented flat fan divider heads maintain the smooth horizontal flow of product as it leaves the primary runs to the divide into each secondary run. This accurate and efficient air delivery system ensures that germination, growth and vigor are protected. Extra-durable metallic paint The silver gray metallic DuPont ™ paint on the 9-SERIES was chosen for its outstanding durability, toughness and resistance. Quick-change sprockets provide simple, reliable adjustments between crops and posi-drive transmission uses a positive lock on all drive sprockets to deliver smooth and reliable metering. Seed and fertilizer rate charts have been added to the tanks to allow for a quick reference when starting calibrations of different products. This reduces the time to select the proper rate sprocket by providing a generic start point. Proper calibrations are still needed to ensure proper selection of the rate sprockets for your machine before seeding is started. Fan speed, shaft rotation, bin levels, acres seeded and other critical data are available with the standard Vansco monitoring system. The variable rate option is quick and responsive for accurate on-the-go rate changes. The VRT option features: • Topcon’s industry-leading X30 console with intuitive multi-view interface. • Morris factory loaded air cart profiles for initial set-up • Variable rate control for up to eight products • Miniview windows with drag-and-drop positioning • Interaction keypads with expandable menus • Dashboard readouts provide constant, convenient data • Full-screen views available for more detailed information • Advanced setup wizard provides simple icon based setup control Quick and responsive Variable Rate Metering Smooth Mechanical Drive Metering BOLD STYLE AND ADVANCED ENGINEERING

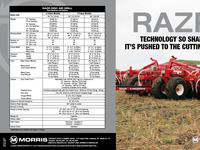

1. www.morris-industries.com MOR – 9 Series Logo_A INSPIRED BY FARMERS, ENGINEERED BY MORRIS Input Control Technology Engineered for Simple Overlap Control The Morris Input Control Technology is engineered to prevent overlaps by stopping product flow over the sections that are not required. The ICT system uses a unique drive system to engage or disengage the individual metering-wheels that stops the product in each tank from flowing instantly. With the simple sprocket-driven system, the metering-wheel is either engaged and turning or is stopped. That way the meter-wheels for each section are always full of seed and fertilizer, which reduces the time required to charge the system when beginning the next pass. The simple sprocket-driven system is visible to the operator when inspecting the tanks and its function is intuitive. The electric GPS system is transmitted to the Topcon X30 controller. The controller then signals the hydraulic valve, which engages or disengages the gear drive system for the metering wheels. The simple on and off set-up gives the operator a much more cost-effective and less complicated way to conserve crop inputs. CORPORATE OFFICE & TRAINING CENTRE - 2131 Airport Drive, Saskatoon, SK Canada S7L 7E1 Tel: 306.933.8585 Fax: 306.933.8626 U.S.A. Toll-Free: 1.866.663.8515 www.morris-industries.com Questions? email: info@morris-industries.com The policy of MORRIS INDUSTRIES LTD. is one of continuing improvement; therefore, the company reserves the right to change any specification without notice. PRINTED IN CANADA 0111.0111.1500 9 SERIES AIR CART Specifications and Options Configuration Tow Between Tow Behind Rear Tow Hitch - 9365 to 9650 Standard (Max 26,000 lb Draft Load) (Max 11,818 kg Draft Load) Optional (9365 to 9650) (Max 15,000 lb Draft Load) (Max 6,818 kg Draft Load) Rear Tow Hitch - 9800 N/A Standard (Max 26,000 lb Draft Load) (Max 11,818 kg Draft Load) Hitch Stand N/A Optional Fan Impeller Diameter 17” (43 cm) - Up to 5,000 r.p.m. Hydraulic Fan Drive (Closed Centre or Closed Centre Load Sensing systems required) Hydraulic requirements for Air Cart only at Rated Fan Speed. 16cc - piston type orbit motor 21 U.S. gal./min. (80 l/min) at 2,750 p.s.i. (18,960 kpa) Dual Fans require 42 U.S. gal./min. (160 l/min) VRT requires an additional 5.5 U.S. gal/min (21 l/min) High Flow Hydraulic Kit Standard Loading Auger Standard (10” Dia) (25.4 cm Dia) Optional - Conveyor(16”) (40.6 cm) Optional - Hydraulic Assist M e t e r i n g - Ground Driven Standard - Variable Rate (VRT) Optional - Topcon Monitor - GPS Compatible VRT Optional - Topcon Monitor Meter Shut Off Electric Number Secondary Runs - Single Shoot 21 to 99 (9800 will do up to 110) Number Secondary Runs - Double Shoot 42 to 198 (9800 will do up to 220) Number Secondary Runs - Triple Shoot Subject to availability Primary Hose - Diameter 2 1/2” (6.4 cm) Secondary Hose - Diameter Standard - 15/16” (2.4 cm) Optional - 1 1/4” (3.2 cm) Easy Clean Out System Standard Meter Drive Option -Second Clutch (For spot fertilizing on the go) Standard (Ground Drive Only) Monitor - ( Shaft Motion (4), Bin Level (4), Fan Speed (2), Acre Tally, Ground Speed) Standard Optional Seed Flow Work Switch (Mounted to Seeding Machine) Optional Mechanical Acre Meter Optional (Ground Drive Only) Tire Specifications Tire Style Rating Pressure BT 9365 9450 BH 9365 9450 BH 9535 BH 9445 9550 9650 BT 9445 9550 9650 BH 9800 500/70 R24 Front Castor Lug LI 157 - 25 psi - - - - 28LR26 Quad Steer Lug 165 A8 - 18 psi 18 psi 18 psi - - 800/65 R32 Lug LI 172 20 psi 20 psi - - - 20 psi 800/65 R32 Dual Wheels Lug LI 172 - - - 20 psi 20 psi 20 psi 900/60 R32 Lug 176 A8 17 psi 17 psi 26 psi 26 psi - - 520/85 R38 Dual Wheels Lug 155 A8 - 20 psi 20 psi 20 psi - - *BH - Tow Behind only *BT - Tow Between only Tank Capacity Model Front Tank Mid 1 Tank Mid 2 Tank Rear Tank Total Weight Tow Behind Weight Tow Between 9365 2 Tank 182 bu 226.5 cu ft 6414 litres N/A N/A 182 bu 226.5 cu ft 6414 litres 364 bu 12828 litres 50/50 Split 10900 lbs 4944 kg 14100 lbs 6396 kg 9450 3 Tank 182 bu 226.5 cu ft 6414 litres 86 bu 107 cu ft 3030 litres N/A 182 bu 226.5 cu ft 6414 litres 450 bu 15858 litres 40/19/40 Split 11900 lbs 5398 kg 15100 lbs 6849 kg 9535 4 Tank 182 bu 226.5 cu ft 6414 litres 86 bu 107 cu ft 3030 litres 86 bu 107 cu ft 3030 litres 182 bu 226.5 cu ft 6414 litres 536 bu 18888 litres 34/16/16/34 13000 lbs 5897 kg N/A 9445 2 Tank 221 bu 275 cu ft 7788 litres N/A N/A 221 bu 275 cu ft 7788 litres 442 bu 15576 litres 50/50 Split 17300 lbs 7847 kg 20000 lbs 9072 kg 9550 3 Tank 221 bu 275 cu ft 7788 litres 107 bu 133 cu ft 3772 litres N/A 221 bu 275 cu ft 7788 litres 549 bu 19348 litres 40/19/40 Split 18000 lbs 8165 kg 20700 lbs 9389 kg 9650 4 Tank 221 bu 275 cu ft 7788 litres 107 bu 133 cu ft 3772 litres 107 bu 133 cu ft 3772 litres 221 bu 275 cu ft 7788 litres 656 bu 23120 litres 34/16/16/34 18700 lbs 8482 kg 21400 lbs 9707 kg 9800 4 Tank 265 bu 330 cu ft 9339 litres 133 bu 166 cu ft 4700 litres 133 bu 166 cu ft 4700 litres 284 bu 353 cu ft 10008 litres 815 bu 28747 litres 33/16/16/35 24000 lbs 10890 kg N/A 9 Se R ie S Ai R C A RT Specifications and Options Configuration Tow Between Tow Behind Rear Tow Hitch - 9365 to 9650 Standard (Max 26,000 lb Draft Load) (Max 11,818 kg Draft Load) Optional (9365 to 9650) (Max 15,000 lb Draft Load) (Max 6,818 kg Draft Load) Rear Tow Hitch - 9800 N/A Standard (Max 26,000 lb Draft Load) (Max 11,818 kg Draft Load) Hitch Stand N/A Optional Fan Impeller Diameter 17” (43 cm) - Up to 5,000 r.p.m. Hydraulic Fan Drive (Closed Centre or Closed Centre Load Sensing systems required) Hydraulic requirements for Air Cart only at Rated Fan Speed. 16cc - piston type orbit motor 21 U.S. gal./min. (80 l/min) at 2,750 p.s.i. (18,960 kpa) Dual Fans require 42 U.S. gal./min. (160 l/min) VRT requires an additional 5.5 U.S. gal/min (21 l/min) High Flow Hydraulic Kit Standard Loading Auger Standard (10” Dia) (25.4 cm Dia) Optional - Conveyor(16”) (40.6 cm) Optional - Hydraulic Assist M e t e r i n g - Ground Driven Standard - Variable Rate (VRT) Optional - Topcon Monitor - GPS Compatible VRT Optional - Topcon Monitor Meter Shut Off Electric Number Secondary Runs - Single Shoot 21 to 99 (9800 will do up to 110) Number Secondary Runs - Double Shoot 42 to 198 (9800 will do up to 220) Number Secondary Runs - Triple Shoot Subject to availability Primary Hose - Diameter 2 1/2” (6.4 cm) Secondary Hose - Diameter Standard - 15/16” (2.4 cm) Optional - 1 1/4” (3.2 cm) Easy Clean Out System Standard Meter Drive Option -Second Clutch (For spot fertilizing on the go) Standard (Ground Drive Only) Monitor - ( Shaft Motion (4), Bin Level (4), Fan Speed (2), Acre Tally, Ground Speed) Standard Optional Seed Flow Work Switch (Mounted to Seeding Machine) Optional Mechanical Acre Meter Optional (Ground Drive Only) Tire Specifications Tire Style Rating Pressure BT 9365 9450 BH 9365 9450 BH 9535 BH 9445 9550 9650 BT 9445 9550 9650 BH 9800 500/70 R24 Front Castor Lug LI 157 - 25 psi - - - - 28LR26 Quad Steer Lug 165 A8 - 18 psi 18 psi 18 psi - - 800/65 R32 Lug LI 172 20 psi 20 psi - - - 20 psi 800/65 R32 Dual Wheels Lug LI 172 - - - 20 psi 20 psi 20 psi 900/60 R32 Lug 176 A8 17 psi 17 psi 26 psi 26 psi - - 520/85 R38 Dual Wheels Lug 155 A8 - 20 psi 20 psi 20 psi - - *BH - Tow Behind only *BT - Tow Between only Tank Capacity Model Front Tank Mid 1 Tank Mid 2 Tank Rear Tank Total Weight Tow Behind Weight Tow Between 9365 2 Tank 182 bu 226.5 cu ft 6414 litres N/A N/A 182 bu 226.5 cu ft 6414 litres 364 bu 12828 litres 50/50 Split 10900 lbs 4944 kg 14100 lbs 6396 kg 9450 3 Tank 182 bu 226.5 cu ft 6414 litres 86 bu 107 cu ft 3030 litres N/A 182 bu 226.5 cu ft 6414 litres 450 bu 15858 litres 40/19/40 Split 11900 lbs 5398 kg 15100 lbs 6849 kg 9535 4 Tank 182 bu 226.5 cu ft 6414 litres 86 bu 107 cu ft 3030 litres 86 bu 107 cu ft 3030 litres 182 bu 226.5 cu ft 6414 litres 536 bu 18888 litres 34/16/16/34 13000 lbs 5897 kg N/A 9445 2 Tank 221 bu 275 cu ft 7788 litres N/A N/A 221 bu 275 cu ft 7788 litres 442 bu 15576 litres 50/50 Split 17300 lbs 7847 kg 20000 lbs 9072 kg 9550 3 Tank 221 bu 275 cu ft 7788 litres 107 bu 133 cu ft 3772 litres N/A 221 bu 275 cu ft 7788 litres 549 bu 19348 litres 40/19/40 Split 18000 lbs 8165 kg 20700 lbs 9389 kg 9650 4 Tank 221 bu 275 cu ft 7788 litres 107 bu 133 cu ft 3772 litres 107 bu 133 cu ft 3772 litres 221 bu 275 cu ft 7788 litres 656 bu 23120 litres 34/16/16/34 18700 lbs 8482 kg 21400 lbs 9707 kg 9800 4 Tank 265 bu 330 cu ft 9339 litres 133 bu 166 cu ft 4700 litres 133 bu 166 cu ft 4700 litres 284 bu 353 cu ft 10008 litres 815 bu 28747 litres 33/16/16/35 24000 lbs 10890 kg N/A 9 Se R ie S Ai R C A RT Specifications and Options Configuration Tow Between Tow Behind Rear Tow Hitch - 9365 to 9650 Standard (Max 26,000 lb Draft Load) (Max 11,818 kg Draft Load) Optional (9365 to 9650) (Max 15,000 lb Draft Load) (Max 6,818 kg Draft Load) Rear Tow Hitch - 9800 N/A Standard (Max 26,000 lb Draft Load) (Max 11,818 kg Draft Load) Hitch Stand N/A Optional Fan Impeller Diameter 17” (43 cm) - Up to 5,000 r.p.m. Hydraulic Fan Drive (Closed Centre or Closed Centre Load Sensing systems required) Hydraulic requirements for Air Cart only at Rated Fan Speed. 16cc - piston type orbit motor 21 U.S. gal./min. (80 l/min) at 2,750 p.s.i. (18,960 kpa) Dual Fans require 42 U.S. gal./min. (160 l/min) VRT requires an additional 5.5 U.S. gal/min (21 l/min) High Flow Hydraulic Kit Standard Loading Auger Standard (10” Dia) (25.4 cm Dia) Optional - Conveyor(16”) (40.6 cm) Optional - Hydraulic Assist M e t e r i n g - Ground Driven Standard - Variable Rate (VRT) Optional - Topcon Monitor - GPS Compatible VRT Optional - Topcon Monitor Meter Shut Off Electric Number Secondary Runs - Single Shoot 21 to 99 (9800 will do up to 110) Number Secondary Runs - Double Shoot 42 to 198 (9800 will do up to 220) Number Secondary Runs - Triple Shoot Subject to availability Primary Hose - Diameter 2 1/2” (6.4 cm) Secondary Hose - Diameter Standard - 15/16” (2.4 cm) Optional - 1 1/4” (3.2 cm) Easy Clean Out System Standard Meter Drive Option -Second Clutch (For spot fertilizing on the go) Standard (Ground Drive Only) Monitor - ( Shaft Motion (4), Bin Level (4), Fan Speed (2), Acre Tally, Ground Speed) Standard Optional Seed Flow Work Switch (Mounted to Seeding Machine) Optional Mechanical Acre Meter Optional (Ground Drive Only) Tire Specifications Tire Style Rating Pressure BT 9365 9450 BH 9365 9450 BH 9535 BH 9445 9550 9650 BT 9445 9550 9650 BH 9800 500/70 R24 Front Castor Lug LI 157 - 25 psi - - - - 28LR26 Quad Steer Lug 165 A8 - 18 psi 18 psi 18 psi - - 800/65 R32 Lug LI 172 20 psi 20 psi - - - 20 psi 800/65 R32 Dual Wheels Lug LI 172 - - - 20 psi 20 psi 20 psi 900/60 R32 Lug 176 A8 17 psi 17 psi 26 psi 26 psi - - 520/85 R38 Dual Wheels Lug 155 A8 - 20 psi 20 psi 20 psi - - *BH - Tow Behind only *BT - Tow Between only Tank Capacity Model Front Tank Mid 1 Tank Mid 2 Tank Rear Tank Total Weight Tow Behind Weight Tow Between 9365 2 Tank 182 bu 226.5 cu ft 6414 litres N/A N/A 182 bu 226.5 cu ft 6414 litres 364 bu 12828 litres 50/50 Split 10900 lbs 4944 kg 14100 lbs 6396 kg 9450 3 Tank 182 bu 226.5 cu ft 6414 litres 86 bu 107 cu ft 3030 litres N/A 182 bu 226.5 cu ft 6414 litres 450 bu 15858 litres 40/19/40 Split 11900 lbs 5398 kg 15100 lbs 6849 kg 9535 4 Tank 182 bu 226.5 cu ft 6414 litres 86 bu 107 cu ft 3030 litres 86 bu 107 cu ft 3030 litres 182 bu 226.5 cu ft 6414 litres 536 bu 18888 litres 34/16/16/34 13000 lbs 5897 kg N/A 9445 2 Tank 221 bu 275 cu ft 7788 litres N/A N/A 221 bu 275 cu ft 7788 litres 442 bu 15576 litres 50/50 Split 17300 lbs 7847 kg 20000 lbs 9072 kg 9550 3 Tank 221 bu 275 cu ft 7788 litres 107 bu 133 cu ft 3772 litres N/A 221 bu 275 cu ft 7788 litres 549 bu 19348 litres 40/19/40 Split 18000 lbs 8165 kg 20700 lbs 9389 kg 9650 4 Tank 221 bu 275 cu ft 7788 litres 107 bu 133 cu ft 3772 litres 107 bu 133 cu ft 3772 litres 221 bu 275 cu ft 7788 litres 656 bu 23120 litres 34/16/16/34 18700 lbs 8482 kg 21400 lbs 9707 kg 9800 4 Tank 265 bu 330 cu ft 9339 litres 133 bu 166 cu ft 4700 litres 133 bu 166 cu ft 4700 litres 284 bu 353 cu ft 10008 litres 815 bu 28747 litres 33/16/16/35 24000 lbs 10890 kg N/A 9 Se R ie S Ai R C A RT Specifications and Options