No Hairpinning

Conquer trash with the Pillar DH Disc Seeder. Direct drill in heavy stubble. Sizes 30' to 60'

.png)

Crop residue is no problem with the Pillar disc seeder. A self-sharpening 18" disc carves the initial trench and the patented seed boot creates a firm seed bed without smearing. Save on residue management and retain moisture with a Pillar.

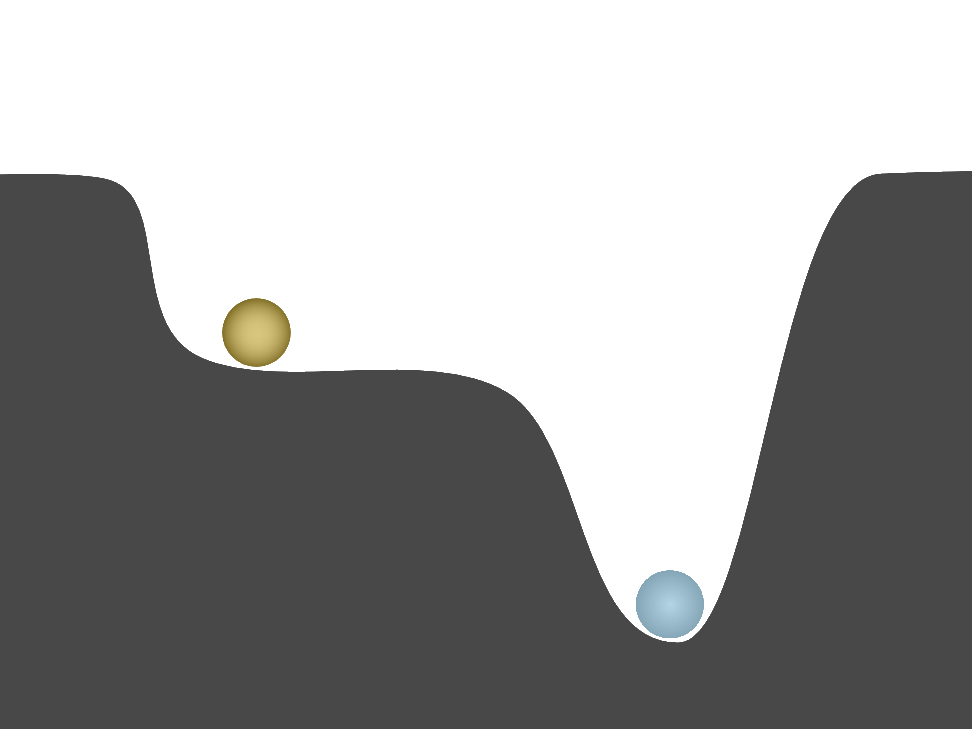

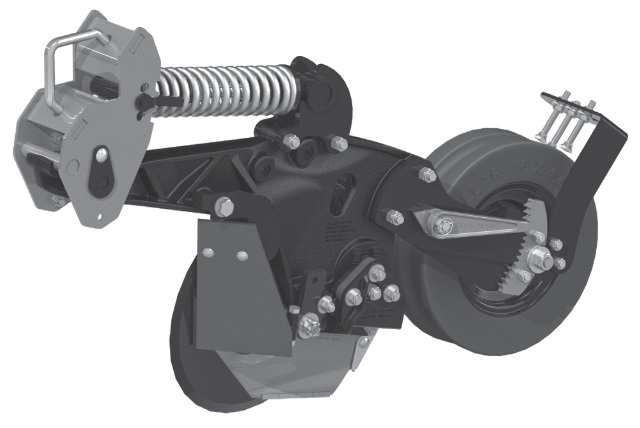

The patented Pillar opener eliminates seed hairpinning by carving a seed bed under even extreme crop residue. The seed boot lifts away soil without smearing the seed bed.

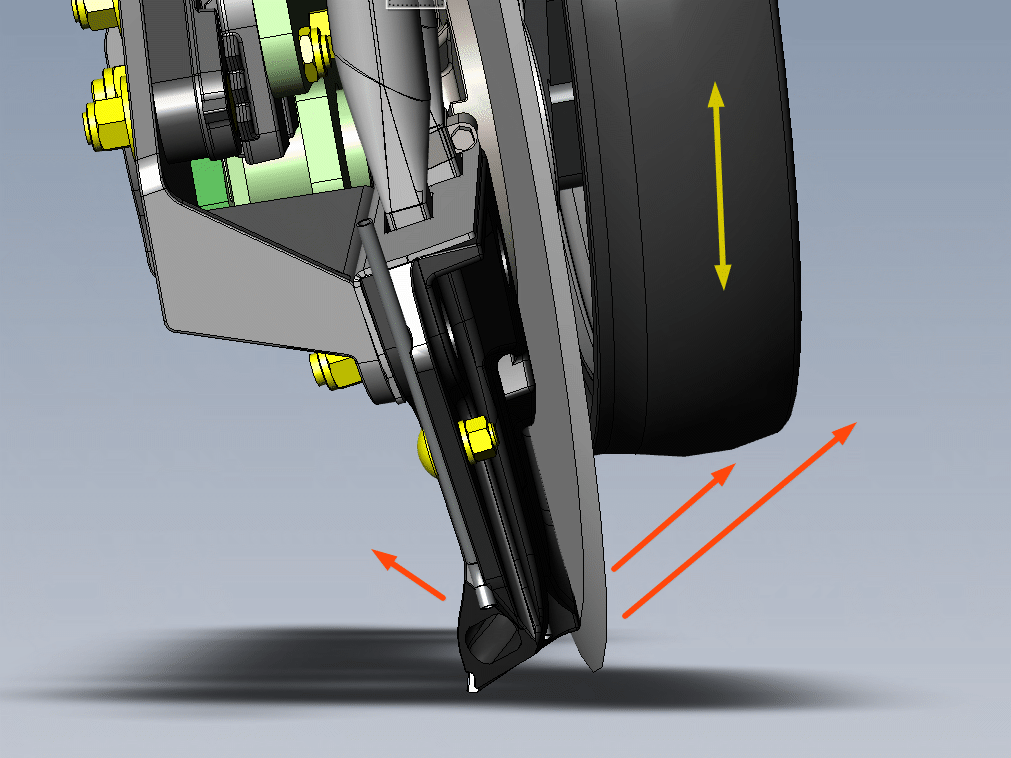

Missing pre-emergents from your cropping program? At 10 km/h the Pillar DH disc seeder generates enough soil throw to incorporate pre-emergent herbicides. The disc cleaning wheel is used to adjust the amount of soil disturbance

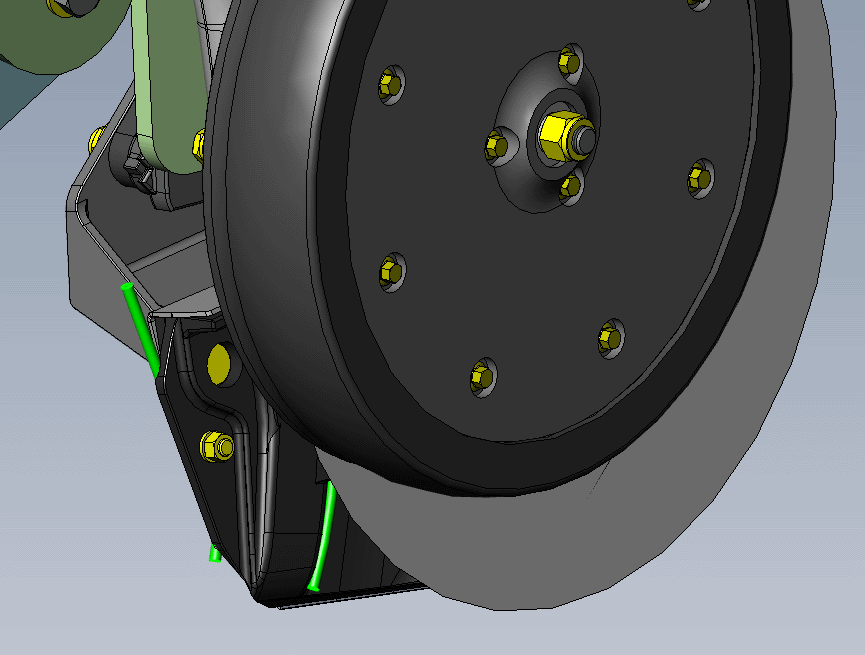

Dual placement off a single opener puts the seed and fertilizer in the optimum locations.

1.5" (38mm) vertical and horizontal separation means using high rates of fertiliser without risking seed burn and precise seed placement.

Different presswheels help the Pillar perform optimally in different soil types. The DS or dual rib is an all-rounder that closes the trench without overpacking the seed. Smooth options work well in sandy soil and the RS is for tricky soils that resist closing.

The key to placing seed and fertiliser on the same opener is the patented Pillar seed boot. A carbide cutting edge creates a stable seed bed without smearing and eliminates hair-pinning in the seed bed.

Soil is thrown mostly off the disc side of the opener with a some from the boot side to clear the seed furrow. Soil throw can be adjusted by changing the height of the cleaning wheel off the ground.

In most conditions the Pillar disc seeder leaves a similar finish to an independent tine machine with defined furrows and ridges. Paddocks with heavy green roots will tend to leave a smoother finish as the root hold the furrow together and do not throw the soil.

Patented Pillar seed boot allows placing of liquids and seed treatments with both the seed and fertiliser.

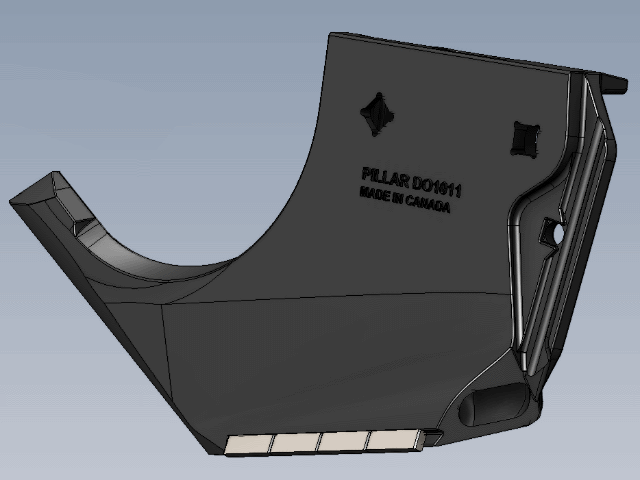

Two grease points per opener and quick change disc hubs means spending more time sowing. Next generation GEN III openers can be optioned with an auto-greaser and frame pivot points are easily serviced with grease banks.

Depth is easily set on the rear presswheel in 1/4" (6mm) increments and the entire bar can be adjusted in minutes. Subframe shims allow small adjustments easily.

Active wing hydraulics and floating hitch keep the Pillar DH seeder following the ground. Independent openers maintain optimum seed sowing depth.

The optional auto greasing system extends bearing life and reduces downtime and maintenance costs. Adjustable grease distributors dispense small measured amounts of lubricant at frequent intervals and prevents dirt and contaminants from migrating into bearings.

The next-generation opener from Pillar keeps the same geometry and seed bed performance as previous models and adds the following:

Compatible with auto greasing system for less maintenance

Even better trash flow

Ease of access grease location

Cast frame is stronger overall

Easy down pressure adjustment

Easier depth adjustment

Self cleaning, hinged trash shield

The best way to know if the Pillar disc seeder is going to work in your conditions is to see it in action. The small plot seeder allows us to easily conduct on-farm demos without the need for a tractor. As well it has all 3 presswheel options mounted to show which one performs the best.

Outperform. We are always looking for the limitation in our equipment but everywhere we have tested the Pillar DH drill has given outstanding results. Whether accurately sowing through 1m standing grass, thick wet mats of residue, or soft irrigation country, the Pillar DH performs.

What can't it do? The Pillar DH drill is not zero-disturbance -- the patented opener creates similar soil movement to a tine machine and allows for incorporating pre-emergent chemicals in the crop management plan. The soil throw can be adjusted with the height of the cleaning wheel but the minimum spacing without infill is 10".

Based in Warman, Saskatchewan, Canada, Pillar was started in 2003 by a number of ex-Flexicoil employees after CNH purchased the company. Dick Friesen worked on the Barton opener in R&D and was approached by Hugh Barton to re-invent the disc opener and develop a double shoot system on a single disc.

As a rule of thumb, the Pillar DH opener at 10km/h requires similar tractor horsepower as an independent tine machine at 7 km/h.

Recommended operating speed is 10.5km/h. You can certainly go faster and still place the seed perfectly but bearing life is reduced and disc deflection can cause wear on the seed boot.

Hydraulic requirements are low. The wings use small amount with the active hydraulic system to transfer weight from the centre section and follow ground contours.

Wear life varies dramatically depending on conditons but as a rule of thumb:

Disc life is approx 20% longer than other 18" single disc openers (due to self-sharpening angle)

Seed boots and disc bearings replaced every second disc

10" and 12" spacing are standard on the Pillar DH frames, with metric and 3m tramlines available on request.

Minimum spacing is restricted to 10" as the opener generates too much soil throw and infill at narrower spacing. The Pillar opener performs more like a tine that can get through any trash than a no disturbance single disc.

Our experience in some trickier soil types:

Sticky: Pillar openers go surprisingly well in sticky ground, especially compared to other discs. Stubble cover helps with shedding mud from the disc. Soil throw is increased from build-up on the seed boot.

Rocks: Rocky ground increases disc wear but the opener does not bring them up like C-shank tine machines.

In general Pillar Openers are only available with the DH frame and can not be retrofitted to other bars. The mounting bar design is critical to the operation of the unit and performance will be sacrificed if mounted on a different frame.

|

Width

|

Spacing

|

# Openers

|

Weight

|

Transport Width

|

| 30' | 10" | 36 |

10,478 kg | 6.15m |

| 30' | 12" | 30 |

10,002 kg |

6.15m |

| 40' | 10" | 48 |

13,713 kg | 6.15m |

| 40' | 12" | 40 |

12,987 kg |

6.15m |

| 50' | 10" | 60 |

18,258 kg | 7.16m |

| 50' | 12" | 50 |

17,418 kg | 7.16m |

| 60' | 10" | 72 |

19,838 kg |

7.16m |

| 60' | 12" | 60 |

18,829 kg | 7.16m |