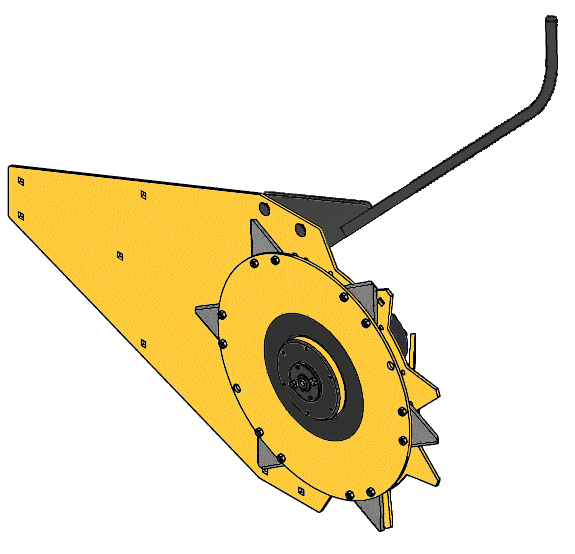

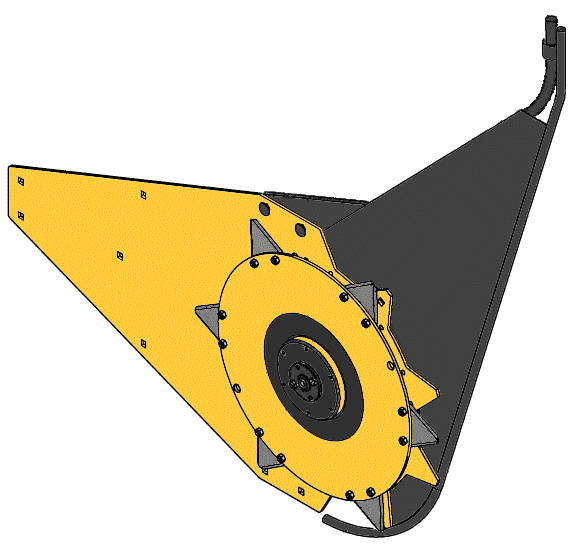

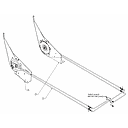

Roto-Shear Vertical Knives Common Unit

RS 27000-00includes Collector Rod and Divider Board

(this will do 1 side of header)

Australian Stock

Contact us for more info

Roto-Shear owners know that when harvesting lodged or tangled crops like canola and peas, this is an essential piece of equipment that they would never be without again. When time matters most, Roto-Shear has proven itself to be dependable in the toughest harvests, cutting through tangled and lodged crops with speed and efficiency.

The simplicity and quality of the design makes it essentially maintenance-free. Roto-Shear customers declare that it is the most durable and reliable windrower crop cutter they have ever used, outperforming everything else on the market.

Made in Canada

Common Questions

Most mounting kits (eg Macdon) require 3 hoses to be made:

From return line on reel

Between the Roto-Shears

To return where other line is removed

As these lines are dependent on the width of the front these are best supplied locally.

AGCO/Massey fronts require a hydraulic flow control valve and all hoses as it is connected to a 3/4" line.

To check if the front has this option, open the crop deflector at one end and check for 2 capped hydraulic hoses. See more images are on the Honeybee 4000 mounting kit page.

It is recommended that the Roto Shear be plumbed in series with an orbit motor on the reel drive on the windrower, preventing the Roto Shear from operating when the machine is shut down.

When it is operating, the cutter runs quietly, therefore, it can be very hazardous.

It is very important to have the orbit motor on the Roto Shear be the last motor in series before the oil returns to the reservoir. This eliminates excessive backpressure in the Roto Shear motor, and possibly cause seal failure. All the Roto-Shear motors have a case drain fitting and this can be connected to tank to reduce risk of shaft seal failure.

On Massey Ferguson fronts, the Roto-Shears are plumbed into the 3/4" sickle drive hydraulic line and require a pressure compensating hydraulic flow control valve to adapt down to 1/2" lines for the Roto-Shears. A case drain is also required on 5200/5400 fronts.

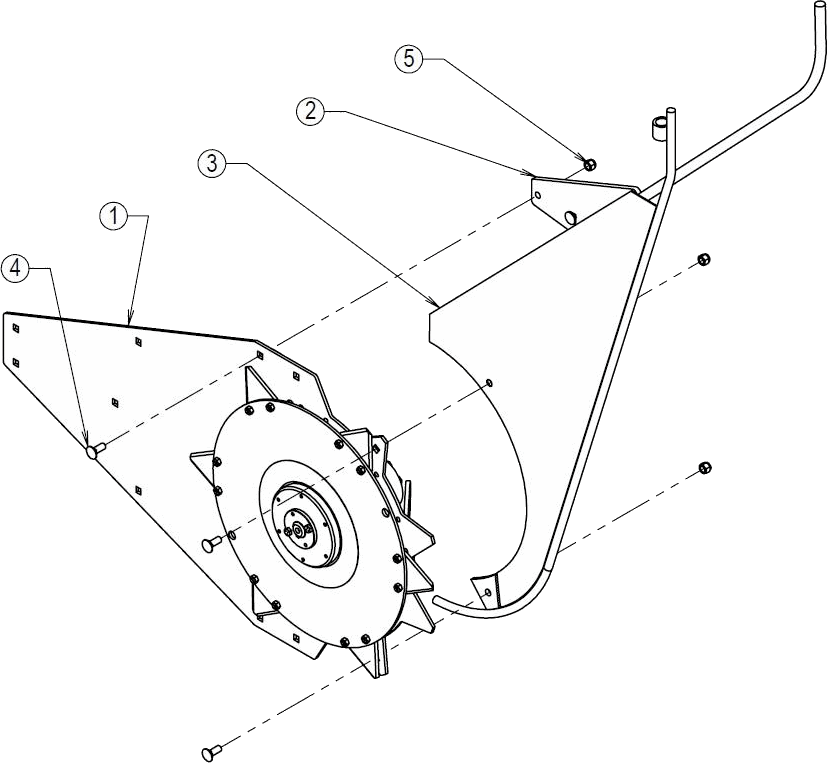

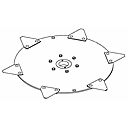

Roto Shear common units come with spare knives that are typically just for spare parts. They can be bolted on the stationary side to improve cutting but it is not very common. It may help in certain situations.